Custom Machinery Solutions, LLC

Specializing In Custom Machinery Design

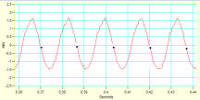

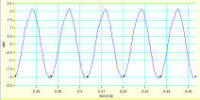

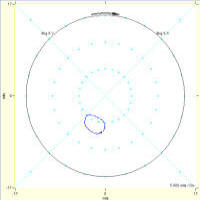

Vibration waveform data (x & y probes) and orbit from generator bearing.

Data taken with proximity probes held by CMS probe mounts.Y Probe mount in position on generator bearing. Extra long probes were used since the distance to the shaft was not known before arriving on site.

Clearance was tight but there was enough room to install both X & Y probes and mounts. The CMS mounts require about 2” of clearance. Note the use of

extension brackets to position the probe centers away from shaft curvature.

Many older turbine-generators do not have duel proximity probes installed at each radial bearing. The 1985 vintage turbine generator shown at right was originally equipped with a single shaft rider at each bearing.

The shaft riders were later replaced with a single Bently Nevada proximity probe.Concern over high vibration at the generator bearings initiated a more detailed inspection using CMS removable probe mounts.

During a post outage startup, two CMS removable probe mounts were installed on the generator to obtain orbit & shaft position data during spin-up and online.

The orbit and shaft centerline plots did not indicate rubs. Oil film development in the bearing was acceptable for the bearing design and clearance.

A balance shot recommendation had been made prior to the outage and these data confirmed that a balance correction was needed to meet the OEM vibration recommendations.

Copyright 2010, Custom Machinery Solutions, LLC